CONTENTS

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Prepare for Emergencies

Wear Protective Clothing

Protect Against Noise

Inspect Machine

General Precautions for Cab

Use Handholds and Steps

Adjust the Operator°s Seat

Ensure Safety Before Rising from or

Leaving Operator°s Seat

Fasten Your Seat Belt

Move and Operate Machine Safely

Handle Starting Aids Safely

Operate Only from Operator°s Seat

Jump Starting

Keep Riders Off Machine

Precautions for Operations

Investigate Job Site Beforehand

Equipment of Head Guard, Rops, Fops

Provide Signals for Jobs Involving

Multiple Numbers of Machines

Confirm Direction of Machine to Be Driven

Drive Machine Safely

Avoid Injury from Rollaway Accidents

Avoid Injury from Back-over and Swing Accidents

Keep Person Clear from Working Area

Never Position Bucket Over Anyone

Avoid Undercutting

Avoid Tipping

Never Undercut a High Bank

Dig with Caution

Operate with Caution

Avoid Power Lines

Precautions for Lightening

Object Handling

Protect Against Flying Debris

Park Machine Safely

Handle Fluids Safely?Avoid Fires

Transport Safely

Practice Safe Maintenance

Warn Others of Service Work

Support Machine Properly

Stay Clear of Moving Parts

Prevent Parts from Flying

Store Attachments Safely

Prevent Burns

Replace Rubber Hoses Periodically

Avoid High-Pressure Fluids

Prevent Fires

Evacuating in Case of Fire

Beware of Exhaust Fumes

Precautions for Welding and Grinding

Avoid Heating Near Pressurized Fluid Lines

Avoid Applying Heat to Lines Containing

Flammable Fluids

Remove Paint Before Welding or Heating

Beware of Asbestos Dust

Prevent Battery Explosions

Service Air Conditioning System Safely

Handle Chemical Products Safely

Dispose of Waste Properly

SAFETY SIGNS/Europe/Asia/Middle and Near East Model Only

SAFETY SIGNS/North America and Oceania Model Only

COMPONENTS NAME

GETTING ON / OFF THE MACHINE

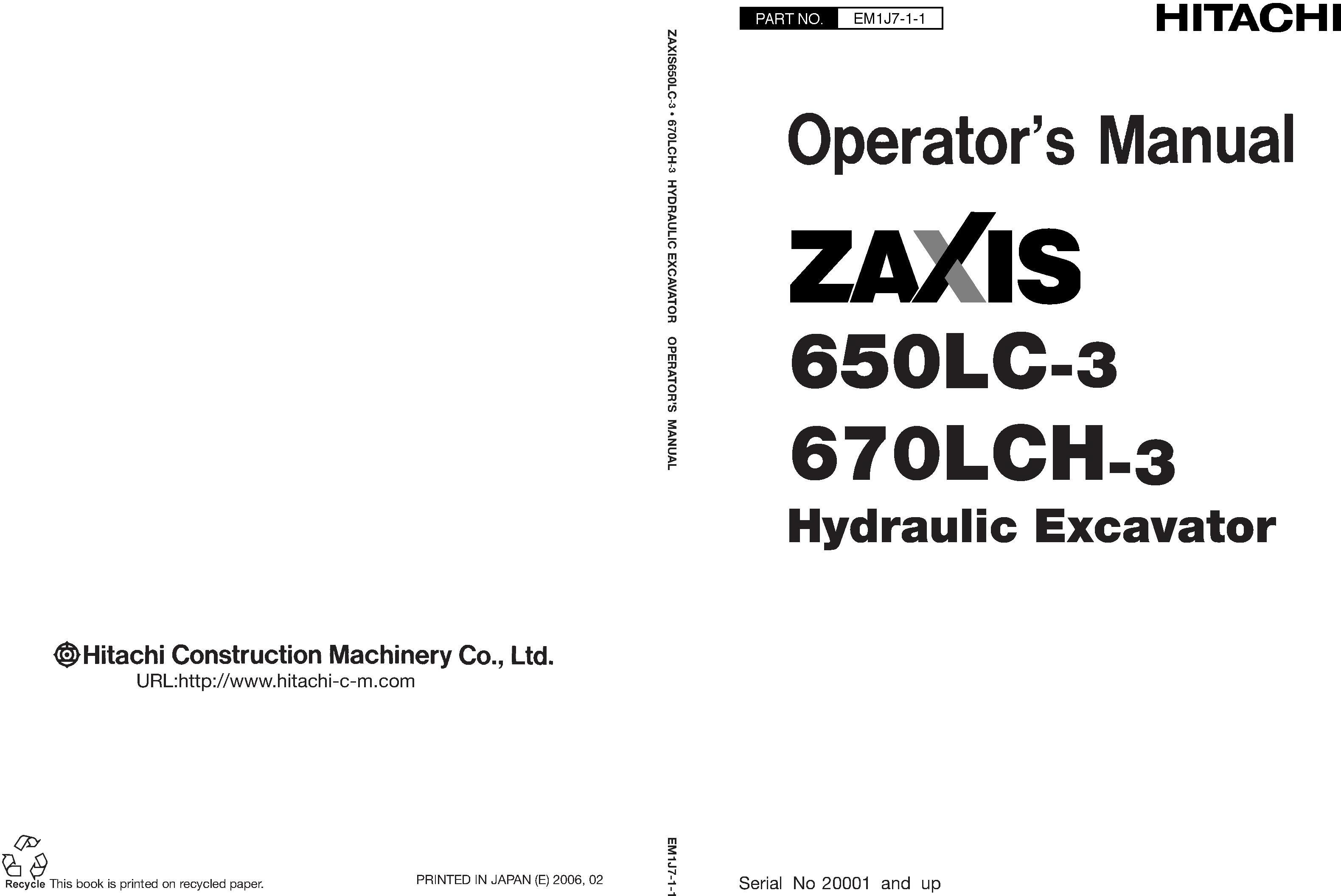

OPERATOR°S STATION

Cab Features

Multi Function Monitor

Outline

Menu Screen (23)

Hour Meter

Fuel Gauge

Clock

Back Monitor Selector

Menu Key

Optional Function Key

Return to Basic Screen Key

Alarm Light

Optional Function Display

Coolant Temperature Gauge

Operating Status Icon Display

Alarm Occurrence Screen

Contents of Alarms

Clock Setting

Attachment Selection (Only Machines Equipped with Optional Parts)

Pump 2 Flow Rate Adjustment (Only Machines Equipped with Optional Parts)

Displaying Operating Conditions

Fuel Rate Display/No Display

Back Monitor Settings

Maintenance Settings

Language Settings

Switch Panel

Engine Control Dial

Auto-idle Switch

Power Mode Switch

Travel Mode Switch

Work Light Switch

Wiper/Washer Switch

Switch Panel (Optional Included)

Fan Rotating Direction Device(Optional)

Key Switch

Power Boost Switch

Horn Switch

Cigar Lighter

Cab Light

Installing Fire Extinguisher (Optional)

Pilot Control Shut-off Lever

Engine Stop Switch

Fuse Box

Additional Fuse Box

Air Conditioner Operation

Auto Air Conditioner

Cab Heater Operation

Cooling Operation

Defroster Operation

Tips for Optimal Air Conditioner Usage

AM/FM Radio Operation

Digital Clock Setting Procedure

Cab Door Release Lever

Opening Upper Front Window (ZAXIS650LC-3)

Closing Upper Front Window

Removing and Storing Lower Front Window (ZAXIS650LC-3)

Opening Side Windows

Opening/Closing Overhead Window (ZAXIS650LC-3)

Opening/Closing Overhead Window

Emergency Exit(ZAXIS650LC-3)

Emergency Exit(ZAXIS670LCH-3)

Adjusting the Seat

Adjusting the Seat (Heater Seat Optional)

Seat With a Built-in Heater

Adjusting the Air-suspension Seat (Optional)

Seat With a Built-in Heater

Adjusting Console Height

Seat Belt

BREAK-IN

Observe Engine Operation Closely

Every 8 Hours or Daily

After the First 50 Hours

After the First 100 Hours

OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Before Starting Engine

Level Check

Starting the Engine in Ordinary Temperature

Starting in Cold Weather

Check Instruments After Starting

Using Booster Batteries

Stopping the Engine

DRIVING THE MACHINE

Drive the Machine Carefully

Steering the Machine Using Pedals

Steering the Machine Using Levers

Travel Mode Switch

Travel Alarm (Optional)

Operating on Soft Ground

Raise One Track Using Boom and Arm

Towing Machine a Short Distance

Operating in Water or Mud

Parking the Machine on Slopes

Parking the Machine

OPERATING THE MACHINE

Control Lever (ISO Pattern)

Control Lever (HITACHI Pattern)

Pilot Control Shut-off Lever

Engine Speed Control

Auto-Idle

Work Mode

Work Mode Select

Power Boost

Power Mode

Operating Backhoe

Grading Operation

Precaution for Arm Roll-in/ Bucket Roll-in Combined

Operation

Avoid Abusive Operation

Operating Tips

Select Correct Track Shoes

Object Handling --- If Equipped

Overnight Storage Instructions

ASSEMBLING

Precautions for Assembling

Precautions for Slinging Work

Precautions for Operating Machine

Installing Counterweight

Installing Boom Cylinder

Installing Boom

Connecting Hoses Between Boom Cylinder and Machine

Installing Boom Cylinder Rod

Installing Arm

Connecting Arm Cylinder Rod

Connecting Bucket Cylinder Hoses

Installing Bucket

Final Inspection

Transporting by Road

Transporting the Machine by Trailer

Loading/Unloading on a Trailer

Retracting or Extending the Side Frame

Retracting the Side Frame

Extending the Side Frame

Types of Packings for Transportation

Packing Dimensions and Weights for Transportation-1 (Backhoe)

Packing Dimensions and Weights for Transportation-2 (Backhoe)

MAINTENANCE

Correct Maintenance and Inspection Procedures

Check the Hour Meter Regularly

Use Correct Fuels and Lubricants

Prepare Machine for Maintenance

Hood and Access Covers

Periodic Replacement of Parts

Maintenance Guide

AGreasing

Automatic Lubrication --- If Equipped

Front Joint Pins (Backhoe)

Swing Bearing

Electric Grease Gun --- If Equipped

Swing Internal Gear

BEngine Oil

Engine Oil Level

Change Engine Oil

Replace Engine Oil Filter

CTransmission Oil

Pump Transmission

Swing Reduction Gear

Travel Reduction Gear

DHydraulic System

Inspection and Maintenance of Hydraulic Equipment

Check Hydraulic Oil Level

Drain Hydraulic Oil Tank Sump

Change Hydraulic Oil

Suction Filter Cleaning

Replace Hydraulic Oil Tank Filter

Replace Pump Drain Filter

Replace Pilot Oil Filter

Replace Air Breather Element

Check Hoses and Lines

Service Recommendations for Hydraulic Fittings

EFuel System

Drain Fuel Tank Sump

Check Water Separator

Replace Fuel Main Filter Element

Replace Fuel Pre-filter Element

Clean Feed Pump Strainer

Check Fuel Hoses

FAir Cleaner

Clean the Air Cleaner Outer Element

Replace the Air Cleaner Outer and Inner Elements

GCooling System

Check Coolant Level

Change Coolant

Clean Radiator/ Oil Cooler/ Inter Cooler/

Fuel Cooler Core

Clean Oil Cooler Front Screen

HAir Conditioner

Clean and Replace Air Conditioner

Filter Clean Filter

Check Refrigerant (Gas) Quantity

Check Compressor Belt Tension

Clean Condenser Core

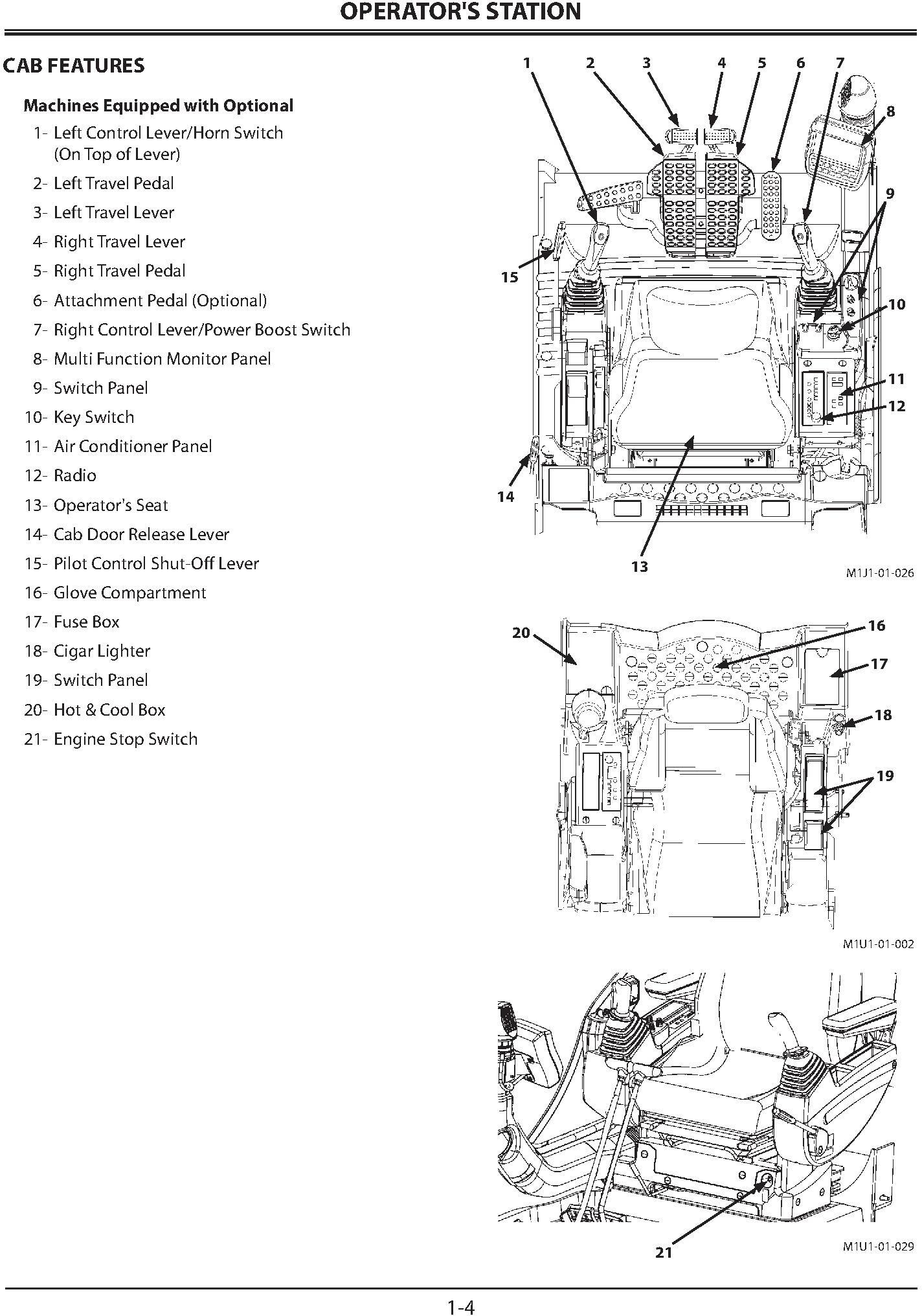

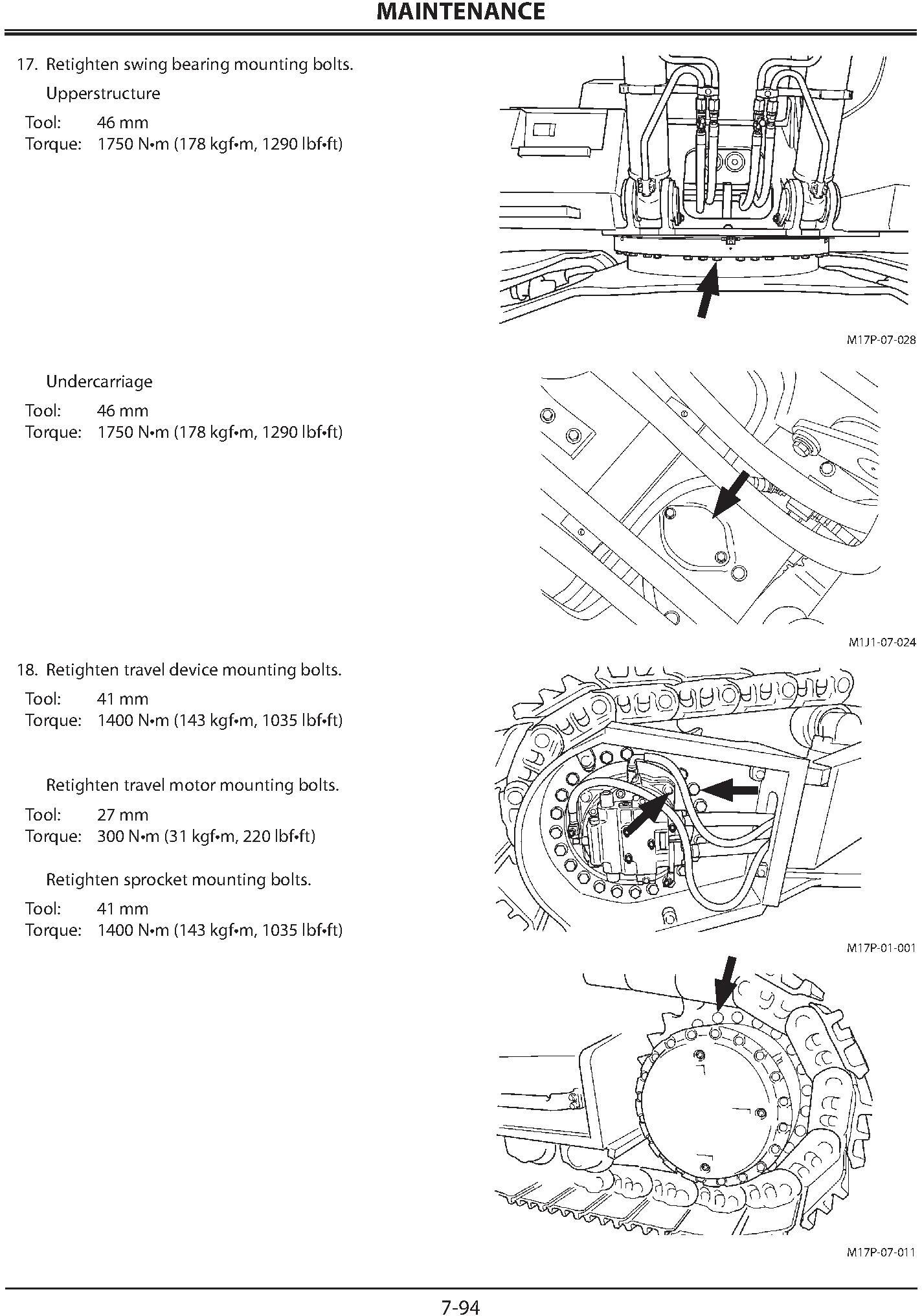

Check Looseness at Each of Fastened Areas

Check in-season and Off-season

IElectrical System

Batteries

Replace Batteries

Replacing Fuses

Fuse Box

Additional Fuse Box

JMiscellaneous

Check Bucket Teeth

Change Bucket

Adjust the Bucket Linkage (Backhoe)

Remove the Travel Levers

Check and Replace Seat Beltcheck

Check Windshield Washer Fluid Level

Check Track Sag

Clean Cab Floor --- As Necessary

Check Tightening Torque of Bolts and Nuts

Check O-rings in Bucket Joints

Retighten Cylinder Head Bolt

Inspect and Adjust Valve Clearance

Check Fuel Injection Timing

Measure Engine Compression Pressure

Check Starter and Alternator

HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT

Hydraulic System

Main Circuit

Electrical Circuit

Electrical Diagram

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

Maintenance Under Special Environmental Conditions

STORAGE

Storing the Machine

Removing the Machine from Storage

TROUBLESHOOTING

Engine

Electrical System

Control Levers

Hydraulic System

SPECIFICATIONS

Specifications (Backhoe)ZAXIS650LC-3

Working Ranges (Backhoe)ZAXIS650LC-3

Shoe Types and Applications ZAXIS650LC-3

Bucket Types and Applications ZAXIS650LC-3

Specifications ZAXIS670LCH-3

Working Ranges ZAXIS670LCH-3

Shoe Types and Applications ZAXIS670LCH-3

Bucket Types and Applications ZAXIS670LCH-3

Lifting Capacities

Sound Level Results (2000/14/EC)

Vibration Level

OPTIONAL ATTACHMENTS and DEVICES

Hydraulic Breaker

Work Mode

Breaker Operation

Precautions for Breaker Operation

Breaker Maintenance

Replace Breaker Circuit Return Oil Filter

Hydraulic Crusher

Stop Valve Operation

Three-way-valve Operation (Machines Equipped with the Piping Common to Hydraulic Breaker and Crusher Operation)

Flow Combining Valve Operation

Precautions for Crusher Operation

INDEX.